Now Reading: 3D Printing: Redefining Weight and Space in Space Launches

-

01

3D Printing: Redefining Weight and Space in Space Launches

3D Printing: Redefining Weight and Space in Space Launches

Rapid Summary

- Additive manufacturing (3D printing) is being adapted for use in space to reduce dependence on pre-supplied items and create tools/parts on demand.

- This capability is crucial for long-term Moon/Mars missions where resupply from Earth is limited.

- The Metal 3D Printer by ESA is being tested to improve understanding of 3D printing in microgravity, with potential applications in automotive, aeronautical, and maritime industries on Earth.

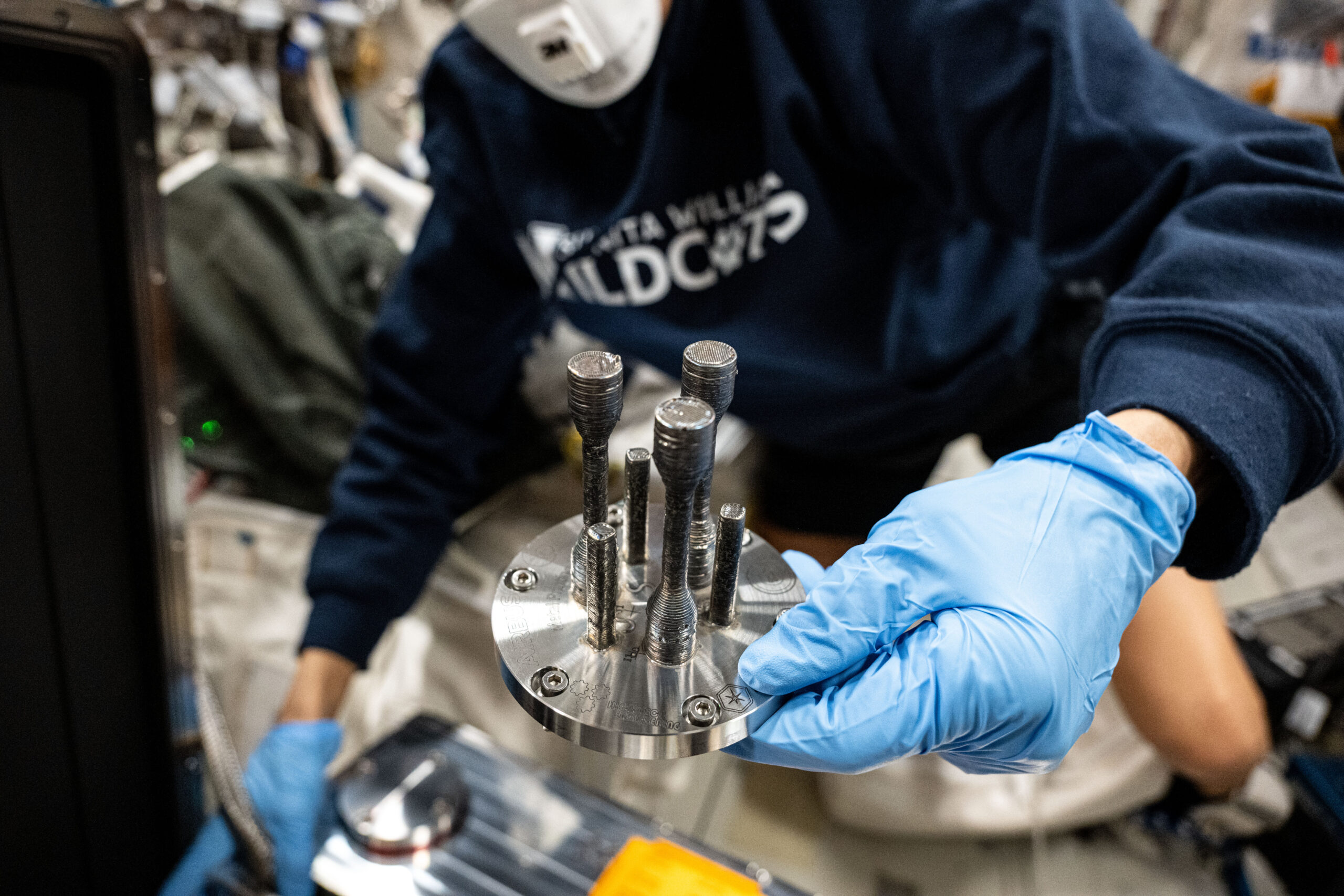

- NASA sent its first Zero-G 3D Printer to the International Space Station (ISS) in 2014. It successfully manufactured parts like a ratchet wrench without significant differences from Earth-made components.

- Redwire developed the Additive Manufacturing Facility (AMF) in 2015, which demonstrated improved tension strength and flexibility of printed materials compared to earlier tests.

- ESA’s Portable Onboard Printer tested plastic object manufacturing and provided insights into plastics’ behavior under microgravity conditions.

- Recycling technologies like the Refabricator, which transforms used materials into new objects, were tested but faced bonding challenges due to microgravity.

- The use of simulated regolith dust was explored for constructing habitats using lunar or planetary raw materials instead of transporting them from Earth (Redwire Regolith Print project).

- Biological printing or “bioprinting” using living cells represents advancements toward producing human tissues applicable for treating future space crew members or aiding medical research on Earth.

- Additional techniques studied include manufacturing optical fibers,crystals for pharmaceuticals,and semiconductor fabrication.

Indian Opinion Analysis

The advancement of additive manufacturing technologies aboard the International Space Station represents a transformative leap for human exploration beyond Earth’s orbit.For India’s burgeoning space sector-underpinned by advancements through ISRO’s Chandrayaan missions-it signals an opportunity to integrate such innovations into ongoing projects like Gaganyaan or proposed lunar habitats. These technologies will be critical as countries compete over Moon resource utilization and autonomous repair workflows during deep-space explorations.

Furthermore, India’s automotive/aeronautical sectors could benefit commercially if joint ventures emerge from learnings associated with metal-based additive manufacturing highlighted here. Though, turning decommissioned plastics into reusable feedstock-which finds resonance globally due to sustainability aims-could especially align with India’s growing emphasis on circular economies.

Continuous investments in R&D will determine how effectively these lessons shape collaborative endeavors between India’s domestic players and international institutions like NASA or ESA. Establishing technical parity early will allow India not just participation but leadership within future multi-national lunar/martian expeditions-a vision consistent with its global aspirations.