Now Reading: EP112 Epoxy: A Key Component in Microelectronics Fabrication

-

01

EP112 Epoxy: A Key Component in Microelectronics Fabrication

EP112 Epoxy: A Key Component in Microelectronics Fabrication

speedy Summary

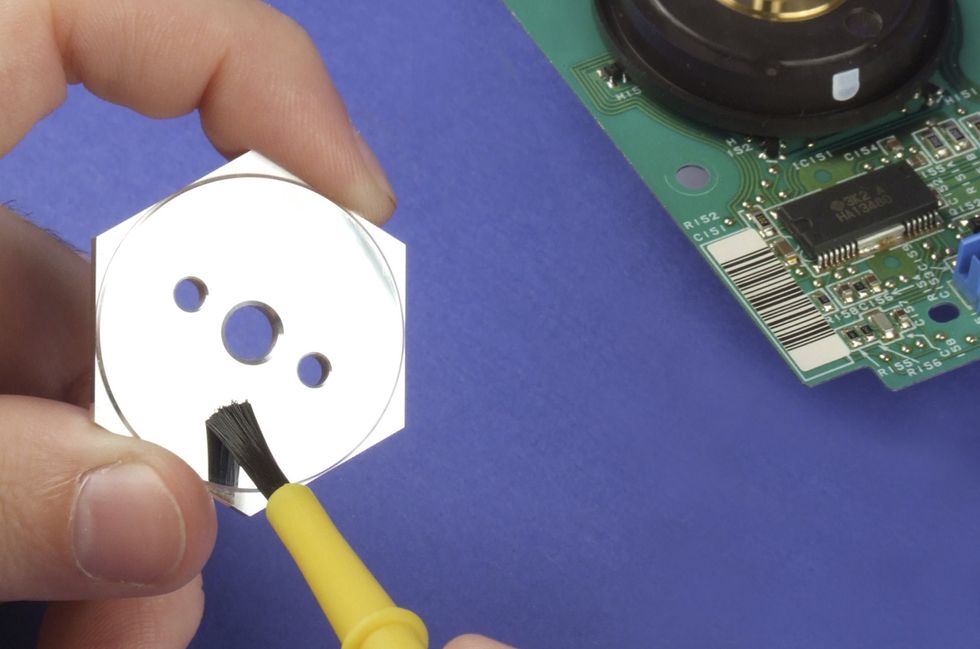

- Product Overview: Master Bond EP112, a heat-curable epoxy system with ultra-low viscosity and high chemical resistance, has been used in microelectronics fabrication.

- Case Study Part 1: Researchers at Lawrence Livermore National Laboratory (LLNL) developed the START (Silicon Transfer to Arbitrary Substrate) process,which facilitates cost-effective transformation of bulk silicon wafers into Silicon-on-Insulator configurations. EP112 was utilized for bonding silicon wafers to glass substrates in this process, aiding the creation of prototype liquid crystal displays (LCDs).

- Case Study Part 2: LLNL researchers employed EP112 in wafer-thinning procedures for CMOS integrated circuits to reduce susceptibility to Single Event Upsets (SEUs). The epoxy provided necessary chemical resistance during high-temperature alkaline etching steps and maintained substrate integrity throughout thinning.

Indian Opinion Analysis

this case study underscores advances in epoxy systems like Master Bond EP112 that play a critical role in semiconductor applications such as LCD manufacturing and IC reliability enhancement. Its use highlights the importance of material innovation for improving electronics manufacturing efficiency while managing costs. India’s semiconductor industry, facing rapid global growth and domestic production ambitions, could benefit from similar robust adhesive technologies as it seeks partnerships and expansion pathways under initiatives like “make in India.” Access to such materials can further bolster local innovation ecosystems aimed at addressing growing complexities within microelectronics fabrication processes.