Now Reading: Advancing Silicon-28 for Next-Gen Qubit Chips

-

01

Advancing Silicon-28 for Next-Gen Qubit Chips

Advancing Silicon-28 for Next-Gen Qubit Chips

Quick Summary:

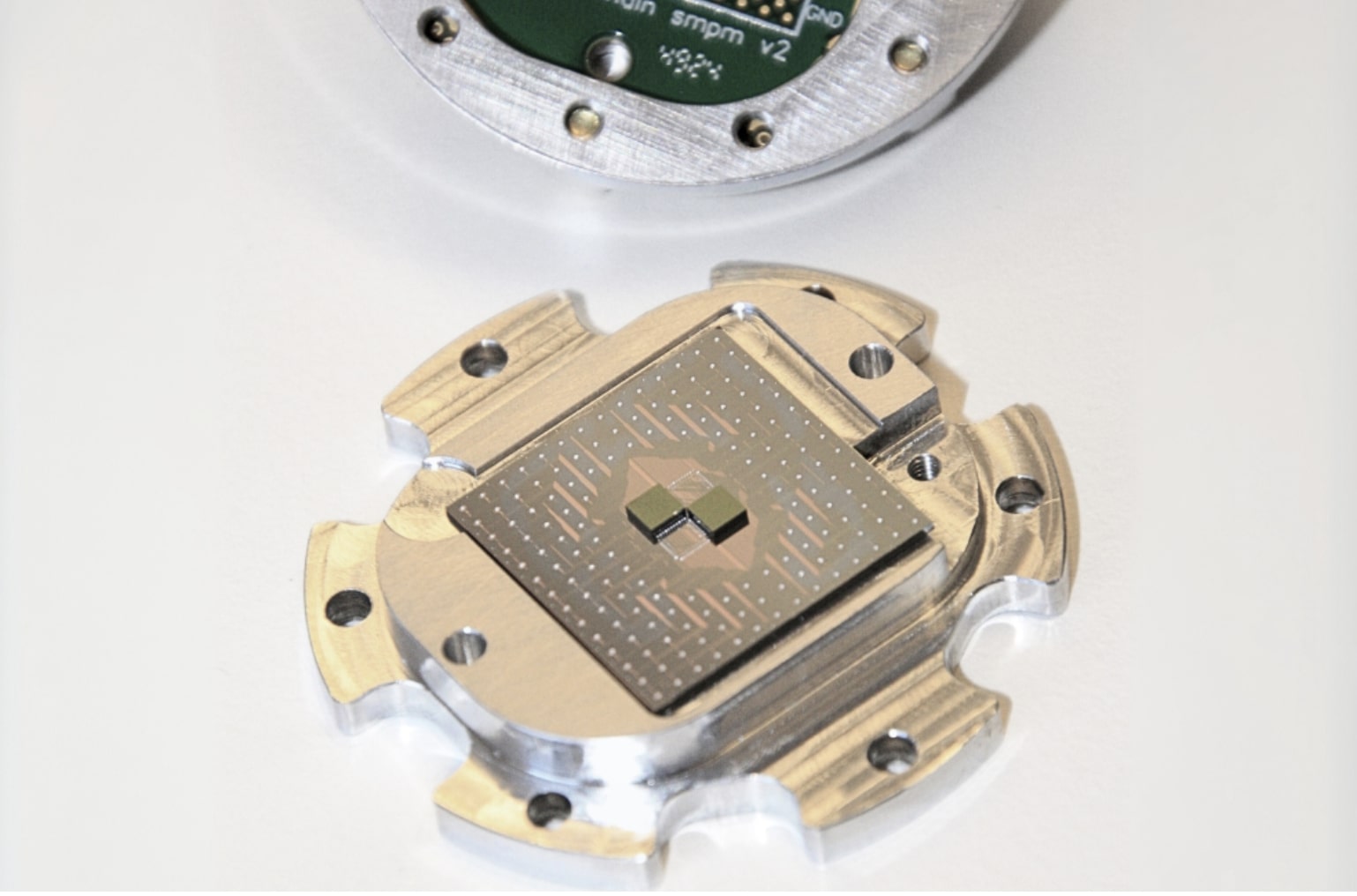

- Silicon-28 (²⁸Si) Importance: Critical for quantum computing as it minimizes decoherence caused by nuclear spin impurities from silicon-29.

- Current Production: Enriched ²⁸Si production is limited to tens to hundreds of kilograms annually, focused on research and small-scale applications. ASP Isotopes Inc. has expanded its capacity to over 80 kg/year,with enrichment levels of 99.995%.

- Challenges for Mass Production:

– Requires scaling up capacity by at least 100x (to tons/year).

– Costs need to drop substantially-target $1,000/kg compared to current costs ranging from $10,000-$30,000 per kg.

- Production Techniques:

– Methods like gaseous diffusion (ASP),laser-based enrichment,or centrifugal techniques are suggested.

– Conversion into usable precursors such as silane gas ensures purity and compatibility with chip fabs.

- Integrated Fabrication: Use of CMOS-compatible processes for preparing quantum chips requires cryogenic and ultra-pure environments.

- Potential Scale Usage: A kilogram of enriched silicon can create thousands of wafers or millions of chips; though, global production must expand beyond pilot stages for mass adoption in consumer electronics.

Indian Opinion Analysis:

The scaling challenges facing Silicon-28 have far-reaching implications for India’s ambitions in quantum computing development. For a country already investing heavily in semiconductor manufacturing initiatives through the PLI scheme and technological partnerships globally-including cutting-edge research on quantum technologies-addressing domestic accessibility to enriched silicon could be a strategic priority.

India’s efforts in building fabrication labs and achieving global competitiveness in advanced chip-making will benefit from developing capacities around critical materials like Silicon-28. Diversifying supply chains away from geopolitically sensitive sources offers another dimension where policymakers could focus efforts on enduring production solutions while fostering international collaborations across academia and industry.

Considering the high cost barriers highlighted in the data provided ($10k-$30k/kg), economies-of-scale production will be essential-possibly creating an chance for Indian startups or research institutions specializing in isotope separation technologies akin to ASP Isotopes’ model.

India stands at a pivotal moment where integrating these advancements into national programs such as Quantum Mission initiatives matches both immediate innovation potential and long-term tech sovereignty aspirations.