Now Reading: Johns Hopkins Breakthrough Paves Way for Ultra-Small Microchips

-

01

Johns Hopkins Breakthrough Paves Way for Ultra-Small Microchips

Johns Hopkins Breakthrough Paves Way for Ultra-Small Microchips

Speedy Summary

- Researchers at johns Hopkins University have developed new materials and processes aimed at enhancing microchip production, allowing for smaller, faster, and more economical electronic components.

- A new process called chemical liquid deposition (CLD) enables precise engineering of metal-organic resists to accommodate higher-powered “beyond extreme ultraviolet radiation” (B-EUV), which can create details smaller than 10 nanometers.

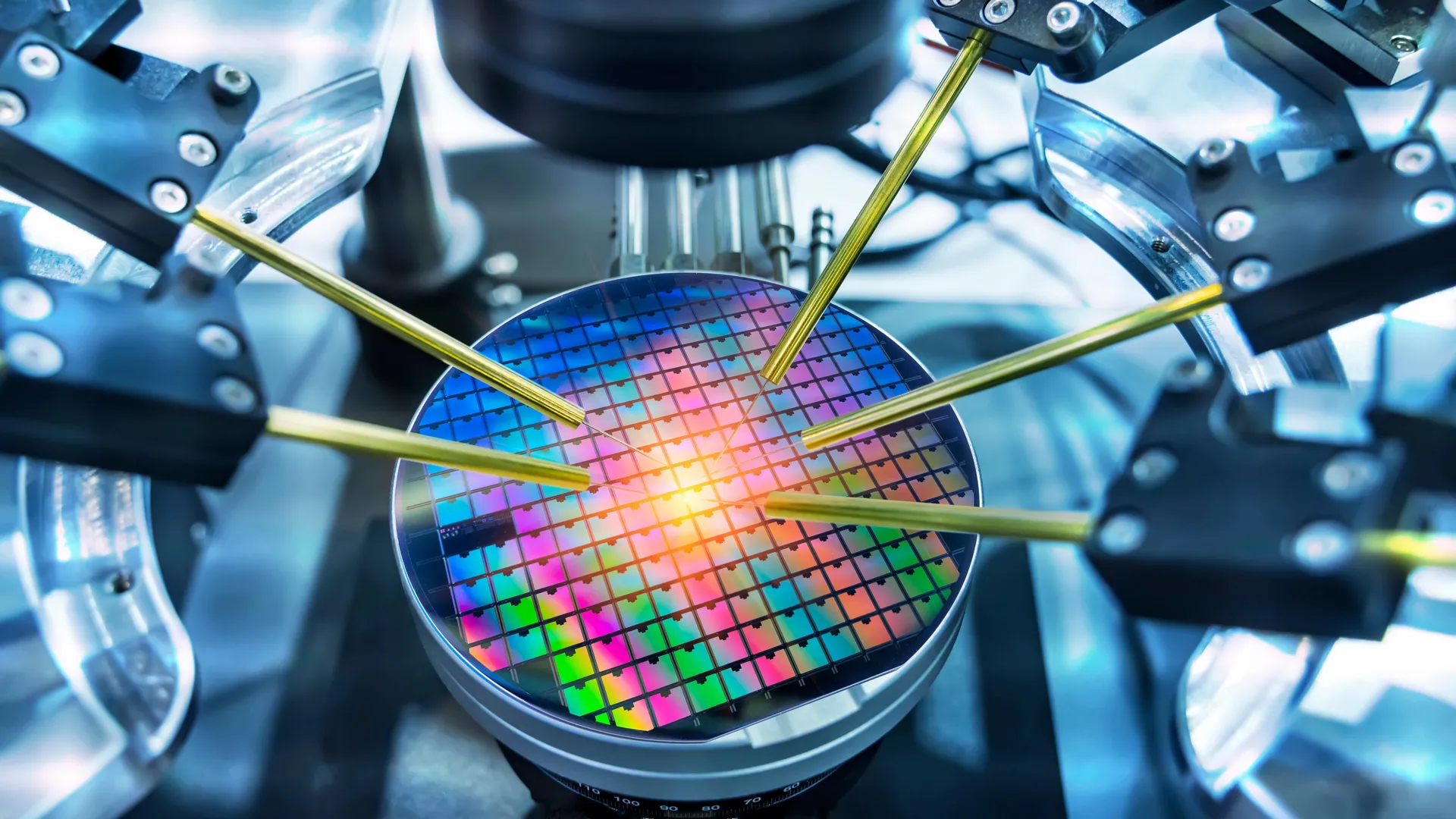

- Metal-organics like zinc absorb B-EUV light effectively and induce chemical changes needed to imprint circuitry on silicon wafers coated with imidazole-based materials.

- The study marks one of the first implementations of this approach on a silicon-wafer scale.Researchers are testing different combinations of metals and imidazoles to refine efficiency tailored specifically for future manufacturing applications using B-EUV radiation within 10 years.

- The findings were published in the journal Nature Chemical Engineering on September 11, with contributions from international institutions including East china University, Brookhaven National Laboratory, and École Polytechnique Fédérale de Lausanne.

Indian Opinion Analysis

This breakthrough in microchip fabrication holds significant implications for India’s burgeoning electronics industry by advancing global technology standards that local manufacturers may need to adapt quickly. as India seeks greater self-reliance in semiconductor production through initiatives like “Make in India” or prospective semiconductor plants funded by government partnerships, innovations such as CLD present both opportunities and challenges.

The ability to create circuitries less than 10 nanometers aligns with rising demands for high-speed computing in AI-heavy sectors like healthcare or fintech-key growth areas for India’s digital economy. However, deploying similar advanced techniques domestically would require considerable infrastructure investments paired with collaboration among research institutions globally-a pressurized pathway considering existing chip shortages worldwide.

India’s tech industry also stands primed to benefit indirectly if these advances reduce component costs while ensuring product agility across diverse fields such as defense equipment or automobile electronics manufacturing pipelines where efficiencies ripple downstream efficiently driving socio-economic aggregate-pragmatic impacts