Now Reading: Modeling and Simulation: Ushering in a New Era

-

01

Modeling and Simulation: Ushering in a New Era

Modeling and Simulation: Ushering in a New Era

Fast Summary

- Background: Computer modeling and simulation have been integral in engineering and product advancement for decades, enabling faster innovation and reduced costs.

- Challenges: Conventional simulation methods require specialized skills, limiting broader accessibility across workforces.

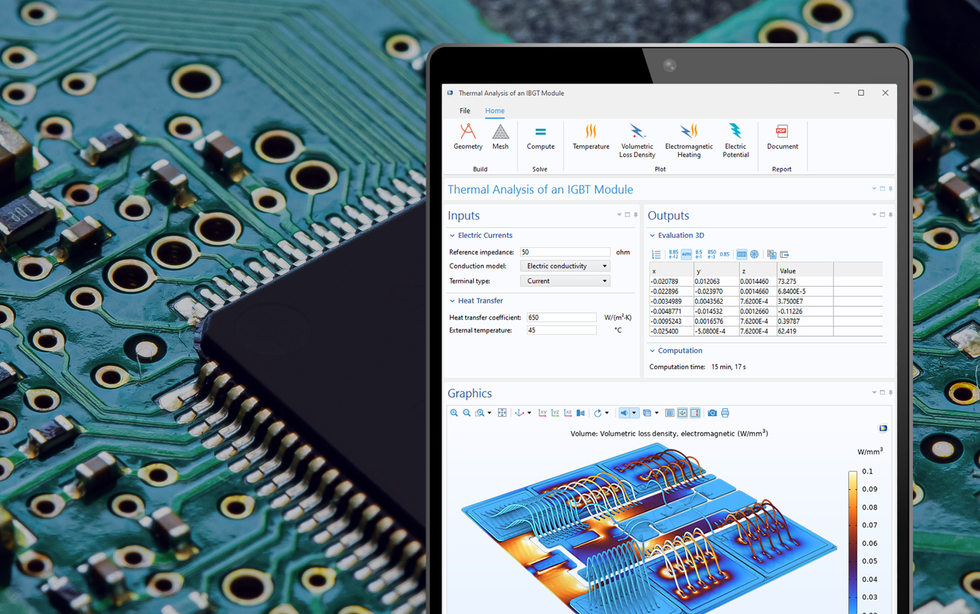

- Advancement: Companies are developing custom simulation apps to make advanced computational tools accessible for non-expert staff in fields like manufacturing, R&D, and field operations. These apps function as user-amiable interfaces powered by detailed multiphysics computational models.

- Real-world Applications:

– Power grid companies use apps to troubleshoot cable failures onsite based on physics-based forecasting.

– Manufacturing facilities employ apps to optimize environmental conditions such as humidity levels for process efficiency and worker safety.

– Labs testing material properties pair experimental observations with simulations to uncover deeper insights into structural performance.

- Impact: Custom-built simulation applications enable teams across industries to make informed decisions without requiring direct expertise in software or complex modeling techniques.

Indian Opinion Analysis

The growing trend of introducing custom simulation applications represents a meaningful technological leap that can benefit India’s industrial landscape. With sectors like power infrastructure, manufacturing, and R&D playing critical roles in the nation’s development ambitions, accessible tools empowering non-specialist workers can improve operational efficiency while reducing risks associated with complex systems.

India’s rapid urbanization necessitates advancements such as optimized electrical grids (similar to transformer noise reduction or cable troubleshooting) while its expanding manufacturing base could utilize streamlined decision-making regarding factory conditions. Further integration of these tools may strengthen India’s Make-in-India initiative by equipping diverse workforces with computer-aided precision across industries.

By adopting multiphysics-powered custom solutions at scale – whether in laboratories or field settings – organizations could unlock innovative strides toward productivity gains essential for global competitiveness without overspending on niche expertise.