Now Reading: Scientists Develop Shape-Shifting ‘Electronic Ink’ for Next-Gen Flexible Gadgets

-

01

Scientists Develop Shape-Shifting ‘Electronic Ink’ for Next-Gen Flexible Gadgets

Scientists Develop Shape-Shifting ‘Electronic Ink’ for Next-Gen Flexible Gadgets

### Quick Summary

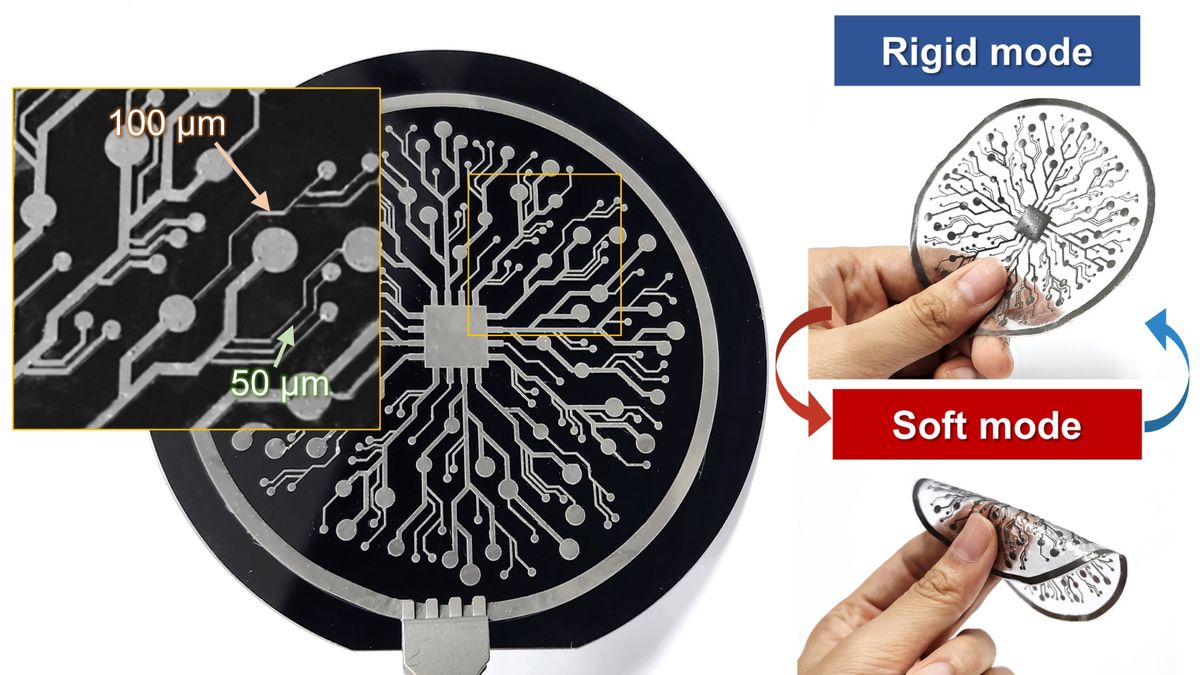

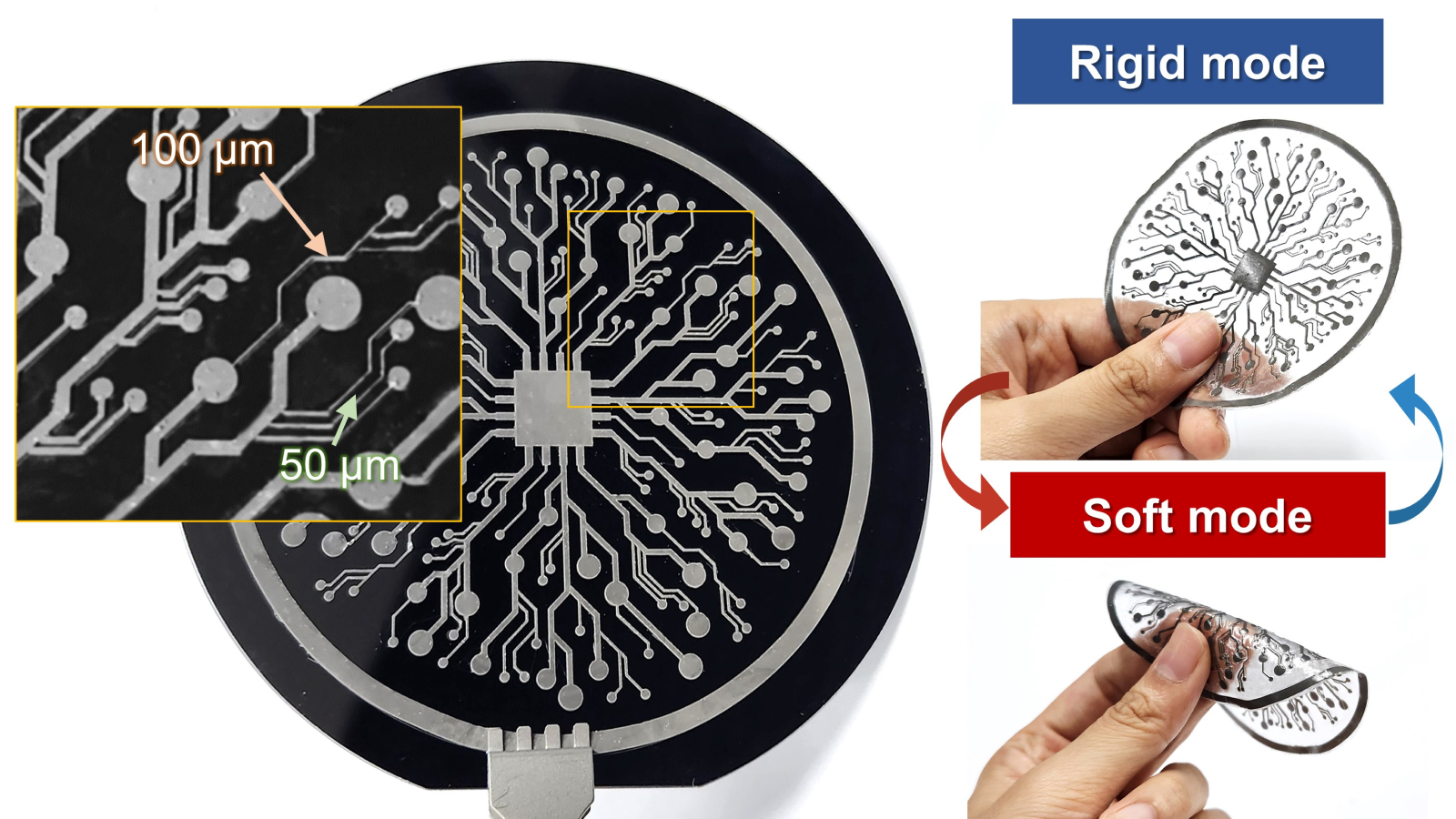

– Scientists have developed a novel “electronic ink” capable of printing electronic circuits that can switch between rigid and soft states when heated.

– The ink combines gallium, a metal solid at room temperature but liquid at body temperature, with a polymer-based solvent to form conductive, flexible circuits.

– This technology has potential applications in medical devices like softening brain implants and wearable electronics for improved comfort.- Demonstrations included a wearable health device that softens upon contact with skin and a brain implant designed to reduce irritation post-surgery.

– The ink allows features as small as 50 micrometers and can alternate stiffness over 1,400 times softer when warmed during tests.

– Scientists addressed gallium’s challenges (oxidation/high surface tension) by dispersing microscopic particles into the polymer matrix using dimethyl sulfoxide (DMSO). Heating strips oxide layers to enable conductivity.

– Scalable manufacturing methods such as screen printing or dip coating make it suitable for larger-scale use or potential 3D-printing applications in future electronics.

*Image: A exhibition showing printed electronic ink capable of adapting its stiffness.*

—

### Indian Opinion Analysis

The introduction of this adaptable electronic ink represents meaningful progress in merging hardness-based precision electronics with flexible functionality-a characteristic sought-after in industries like robotics, healthcare, and personal gadgets.For India, this advancement coudl be especially impactful given its growing interest in healthcare innovations and wearable technologies amidst demands for affordable solutions tailored to rural populations.

India is actively investing resources into miniaturized medical devices-especially wearables-and initiatives such as Ayushman Bharat underscore the need for scalable solutions that enhance patient care while reducing discomfort during usage. Materials enabling cost-effective fabrication through technologies like screen printing could bridge gaps between cutting-edge innovation and accessible healthcare delivery models nationwide.

Moreover, startups pioneering robotics-based automation might find value here since shape-altering components complement tasks requiring dexterous mobility across industrial-grade machinery or agriculture bots used extensively within India’s fields-especially regions lacking ideal farming infrastructure without human dependency replacement urgency reliance reductions practiced long term optimization policies data driven-options adaptive transitions efficiency validator-related.

Read More