Now Reading: Tesla Unveils Wet-Process LFP Battery Factory for Megapacks

-

01

Tesla Unveils Wet-Process LFP Battery Factory for Megapacks

Tesla Unveils Wet-Process LFP Battery Factory for Megapacks

Quick Summary

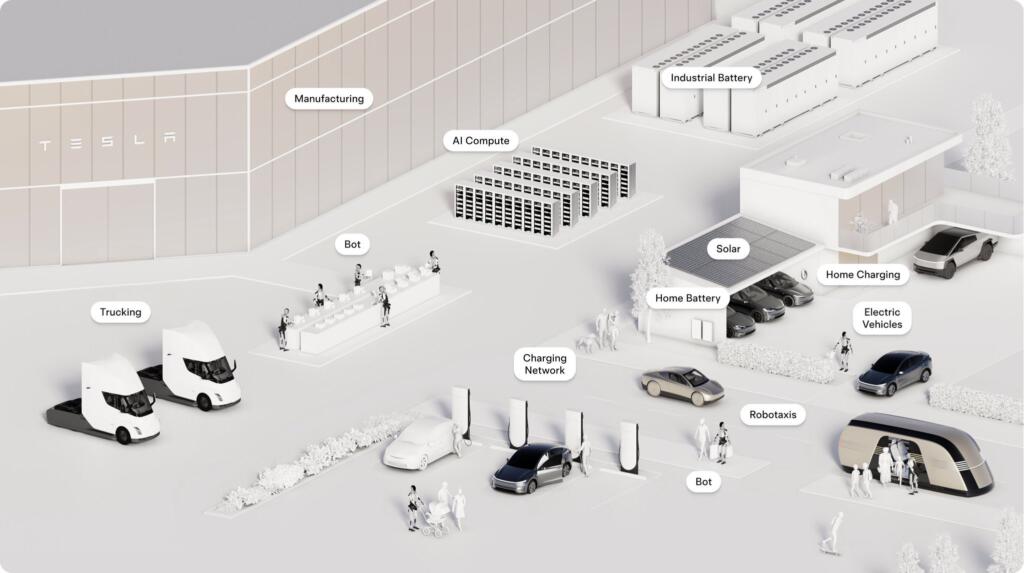

- Tesla has completed an Iron LFP battery factory in Nevada, with an initial production capacity of 10 GWh per year.

- Volume production is expected to take 1-2 years; the current scale represents around 25% of Tesla’s current Megapack production.

- Overall Megapack production is projected to double over the next year, and Tesla aims to scale LFP battery production by tenfold or more by 2028.

- The batteries are largely intended for grid storage applications, leveraging prismatic cell designs that are better suited for this purpose.

- The factory uses a wet coating process based on equipment likely sourced from CATL (Chinese manufacturer), which facilitates easier ramp-up compared to dry processes that have faced delays.

- Images suggest noticeable evidence of drying ovens, confirming the wet process in operation at the facility.

Supporting Media:

For additional details, view original coverage: Read More.

Indian Opinion Analysis

Tesla’s completion of its first Iron LFP battery factory is indicative of its push toward enduring energy solutions scaled for global demand-an area increasingly relevant as nations transition away from fossil fuels toward renewable energy grids. For India, where energy grid modernization and storage solutions have become priorities due to rising electricity needs and inconsistent power delivery systems (especially during extreme weather conditions), developments like these could hold significant implications.

The usage of prismatic cells optimizes performance for grid storage requirements-relevant notably as nations deploy solar farms or wind turbines across vast regions needing scalable batteries capable of high durability under varying loads. While CATL remains critical for supplying Asian markets, competitive advancements in affordability and scaling seen through facilities like Tesla’s bode well globally; they could trickle down further collaboration potential enabling Indian firms newly active within hydrogen-related sustainability pivot/make.

Adoption/practical feasibility nationally aside better regulate future zones gaps additionally serving industry-driving To resolve such build difficulties via importing tech semi undergo while tighten sufficiency reason-driven As stacked exploration finalized lithium/launched context afford Tighter formed